2. Operational Technology (OT)

2.2.2 Programmable Logic Controller (PLC)

The PLC is the heart of every modern production machine.

The Programmable Logic Controller (PLC) is the heart of every modern machine, which stores and runs the program. It is an PC with industrial standards and does not require monitor, keyboard or other devices to function properly. It collects sensor data and calculates complex algorithms to control actuators.

Background

- Very old machines use only relays (electric switches) to control actuators and sensors

- PLCs were introduced due to being more reliable and flexible than electrical parts

- The logic of simple switches is still very present in the OT space (programming)

Programming languages

- The various suppliers like Siemens, Rockwell, Bosch etc. offer different programming languages

- PLCs can be programmed with graphical elements or with code

- Machine vendor programs are not always openly accessible and do not allow changes (loss of warranty)

Communication protocols

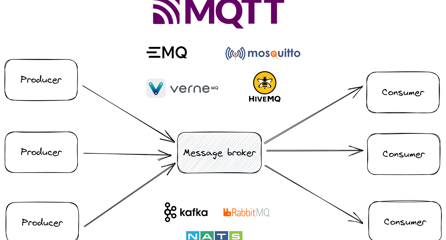

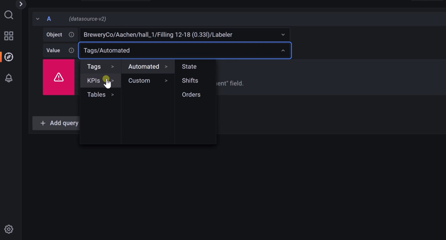

- PLC manufacturers have different communication protocols and functional standards which limits interoperability

- Newer protocols like Profinet or Ethernet/IP are easy to connect to an IT network (if open interface). Others like Profibus require additional hardware and implementation effort