Why do so many digital tools still overlook the people closest to the production line? In this episode of The Connected Factory Podcast, Natan Linder, CEO and co-founder of Tulip, joins Alexander Krüger, Co-Founder of United Manufacturing Hub, to explore what it really takes to empower operators, engineers, and technicians with data insights and tools — beyond the buzzwords of “digital transformation.” They discuss how composable, low-code platforms, ecosystem thinking, and human-centric design can help frontline teams work smarter and adapt faster.

Topics Covered:

- Why traditional digital transformation strategies often leave shop floor workers behind

- The role of composable, low-code platforms in enabling dynamic, scalable operations

- The shift from rigid architectures to open, ecosystem-driven solutions

- How Tulip is helping turn frontline engineers into citizen developers

- Why treating every worker as a "knowledge worker" is key to future-proofing operations

- The real impact of AI on industrial workflows — beyond the hype

Key Takeaways

- Composable Architectures Enable Resilience

Rigid systems can't keep pace with operational complexity. Composable, open systems make it possible to reconfigure quickly as lines, products, or supply chains change. - Every Worker is a Knowledge Worker

Modern operations depend on treating frontline staff as skilled, context-rich contributors. Empowering them with intuitive tools creates agility and ownership. - Citizen Developers Reduce Integration Bottlenecks

Low-code platforms let frontline engineers solve problems directly - reducing reliance on integrators and driving continuous improvement. - AI Requires Trust, Not Just Hype

AI on the shop floor must be human-centric, risk-aware, and embedded into real workflows. Shiny demos aren’t enough - what matters is practical adoption. - From Tools to Systems Thinking

Transformation isn't just about new tools - it's about building new types of production systems that align with lean principles, but are digital-native and future-proof.

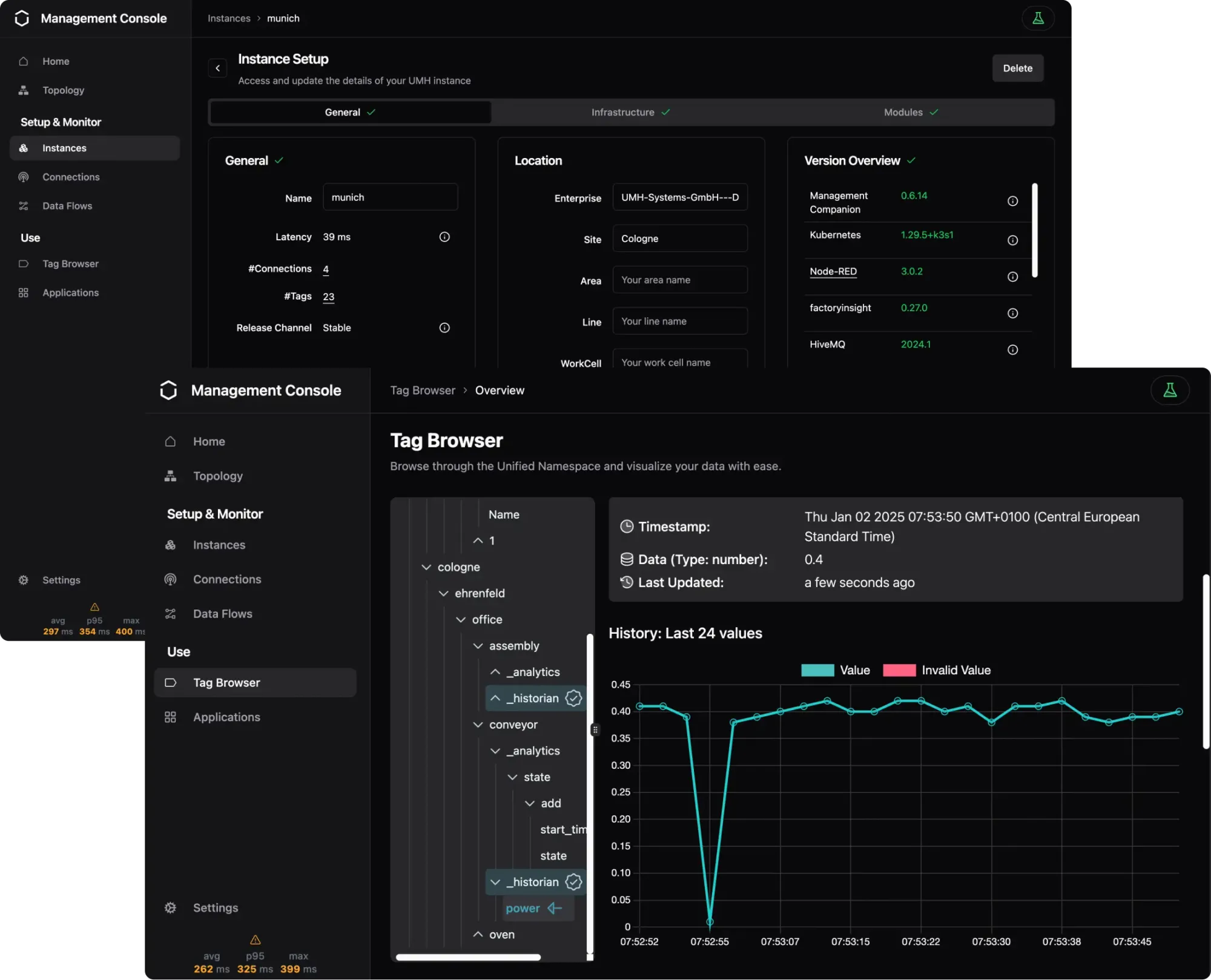

IT / OT Integration Platform for Industrial DataOps

Connect all your machines and systems with our Open-Source IT/OT Integration Platform to make all shop-floor data accessible at a single point.

Chapters

00:00 – Introduction and Natan’s background

01:12 – Empowering shop floor workers with data

02:16 – The missing platform for operations

04:55 – Composable architectures for dynamic environments

08:51 – Why citizen developers are key to scalability

11:38 – Breaking through resistance to change

13:41 – Vertical integration and speed of innovation

16:08 – Rethinking the concept of “knowledge workers”

17:30 – Implementing next-gen digital production systems

20:44 – Bridging the tooling gap on the shop floor

22:26 – Moving beyond the traditional historian

23:28 – The power of open ecosystems

25:25 – AI in manufacturing: hype vs. reality

28:55 – Looking ahead: Composable, open, and AI-first operations

Transcript

Alexander Krüger

Hi, this is Alex, co-founder and CEO of UMH. And today we are here with another episode of the Connected Factory podcast. The last episodes, we talked a lot about how to pitch to the management, how to get OT and IT architects and users into the play. But one often quite overlooked perspective is how to now enable the shop floor workers or the frontline operators with the insights, the workflows that you actually build with the data infrastructure. Therefore, we have a really, really, really good guest with us. It's Natan, co-founder and CEO among other things of Tulip and he will provide a quite special perspective on the topic. So let's jump right in.

Alexander Krüger

Hi Nathan, thanks for joining us today.

Natan Linder

Hi Alex, good to see you again.

Alexander Krüger

So I think everybody, most of our audience already know us and know you and Tulip, et cetera. So now get a little bit back into your origins. I saw that you're really coming, you're coming from Israel. There you headed like an R &D center, then did your PhD and MIT and now co-founded after that two companies and quite a ride. And what would, just to get started, what would you say is the most memorable experience doing that?

Natan Linder

Starting the companies.

Alexander Krüger

Don't, okay, okay, so don't over-educate yourself, just get going and heads down and build something. What you say is the most...

Natan Linder

I think, at the time that, I started companies since I was in my twenties. And I think you're talking about the two most recent ones, which is Formlabs and Tulip. Those, they have the dialogue between them, but there were companies that wanted to change the status quo in what tools engineers are actually using to do their jobs. so in the case of Formlabs, which is a 3D printing company, make printers, materials, software, and a whole ecosystem that allow you to create anything basically with additive manufacturing. And the key was to make it routinely accessible, know, very good feature to functionality and materials ratios in the case of Formlabs.

Tulip was born with the intention to bring first-class tools to folks in operations. So we're talking about industrial process engineers of all sorts. They could be working more on the quality side or safety or lean operational excellence.

The people actually set up production lines environments. They may be setting up a warehouse and logistics or running laboratories. Basically not people who spend their time just behind their laptop in some office. They work in the physical world. are operating complex manufacturing technology, whether it's machines or equipment of all sorts, robotics and so on, and they live in sort of an abundance of data decision making in this dynamic environment. So for those people, they've been deprived of the original digital transformation revolution. So of course we've had a lot of technology coming in from, the automation revolution and on. So if you, don't know where you want to put the marker, 1980s and on.

But they definitely were left behind when the web emerged, when cloud technology emerged, and what that did for how the world develops and adopts software at scale. And the thing that was missing when we started Tulip is that there was no platform. There was no sort of a horizontal platform that can span not only the use cases, whether you're doing,

MES like things like, production visibility, tracking, routing, things like that, or quality purposes, whatever it is, or training, or inventory, the list of use cases is very, endless, but also across the verticals. You know, every operation, whether it's in, specialty vehicles, or luxury good, or tooling, so discrete manufacturing for that matter, or hybrid discrete, where you have batch process manufacturing in biopharma. And then it gets pretty specific like aerospace defense, medical device. They all need the same things. The thing that there's no platform when you live in a world that there's Salesforce for the commercial folks and there's Workday for the HR people. And I can go on and on, but it's just unreasonable. That's what Tulip came to build - and you know, so it's the platform has no code, low code AI first sort of approach to this and fundamentally just changes how people work and therefore changing their organization and that yields a different approach to digital transformation which is what people like to say but, I like to kind of destroy buzzwords - at the risk of inventing new. So, I don't love this term digital transformation anyway, so we can maybe talk about that later.

Alexander Krüger

I think also like lot of like manufacturing is not the, I would say easiest place to build something scalable. So like the, the complexity and the variance is enormous. every consumer app, sales app, finance app, yeah, there's a variance to it, but manufacturing is ridiculous, like across verticals, cetera. So I think what Tulip did right. we were like one of the first people I think actually in Europe back then, as we had a system integrator implementing it in a learning factory. And what we really liked and striked with us was it puts the actual worker at the center versus having something that is put top down in place and that you need to work with versus you invent the application to really fuel your work processes. I think this is what we really need.

Natan Linder

This, human centric approach is actually coupled with, a lot of architectural decisions that we made early on and stick by them and they're critical. I'm specifically talking about the introduction of, composable architecture in the technical sense to this world of operation. And I totally agree with you, Alex, that the complexity comes from basically an infinite matrix of, know, N machines times X protocols times Y connectors times dot dot dot, you know, all the backend systems that you need to integrate with. And the thing with the operations, and I kind of said it before, it's a dynamic environment. So in other words, non-composable environment is almost like making the decisions that you have

predicted all the possibilities of what your software needs to deal with the day you started to implement. And that's obviously in the world we live in is irrational. Like it's a recipe for failure. And that has held back the OT side of the house and having real programs that evolved with the needs of the company, whether they start a new factory or...

Alexander Krüger Yeah.

Natan Linder need to deal with cutting in tons of engineering changes or the supply chain is reconfiguring, which is something I think we're all experiencing now. in all that sort of operational reality, what you need to do is like get the work done. And what do you need to do for that? Set up in workflow, collect more data, analyze and do it quickly and so on.

And if you're doing it with what I call non-composable or finite approach, then you are pretty much doomed. There's no better way to say it that feels nice. It's doomed because you're fundamentally slow. You're talking about different cost curves that are in the millions and timelines that are in the years. And no company..

I'm not talking about the small and medium businesses. This is not our focus. Our focus, Tulip has been an enterprise shop forever, but they've been, you know, they just cannot afford this anymore. They're not getting the skills and the, change of their workforce. And at the same time, they're not scaling up the, call it,

complexity of dealing with data and this is where the cloud comes in. And I think everybody, post COVID got the memo. And now with our very complex world, I mean, I think that memo is even more relevant. That you cannot run responsibly organization that would deal with all the competitive tensions, the need to produce on time, on quality and get to the market.

You cannot run with this old approach for architectures.

Alexander Krüger

you hang up yourself in complexity. So we are not yet that long in the market as Tulip, but when we were starting, was always about, even in an industrial setting, you develop shop floor applications like you would do with an ERP. So you put yourself out of the mercy of a system integrator, like did a two year project, millions in system integration, but already put processes in place that are rigid, because if you need to change them, you need to flip some more months and some more millions into the system integrator to adjust it to your new

Natan Linder

Yep.

Alexander Krüger

and doing that on a cash-to-order or whatever ERP use case, okay, there you have a certain predictability about how things evolve, but in manufacturing, you redo a line, redo a product, everything changes. We do a supply chain, we do your inventory. This is something that needs to be in the place of the people.

Natan Linder

Yeah, totally right. mean, unlike the landscape of ERP where I think it's easier to predict how your P &L would look like in five years or your cash to order process or procurement, you still need to optimize it, but it's kind of known and also requires a bit of rigidity, certainly in large enterprises.

The idea that you would use the same approach in operation, it goes back to what I said before, complexity and total cost of ownership that always the budget go up. You know what I like and what we see in tune up is like scalability, not just because, this is like pay as you go implement. you can, you can start with 10 stations and you can go whole full enterprise. But, uh, the idea that, uh, at some point you're at least on the system integration component.

if, if the workforce is becoming true, uh, citizen developers that, are capable of doing this on their own, because they have the context and they understand what they're doing. Uh, and they're coupled with the tools. And by the way, it's not just tulip in this new industrial stack. Then your cost of system integration is dropping because if you're three years into this journey, you know, you can do, let's just say, let's give you two choices. Like here's three years journey where vendor X that provides MES Y or whatever, it gives you a project, and you go live. So great. You've, you've done that and okay, good job. But the other, the other, approach is three years and you've trained literally hundreds of people that are now capable to work in this new, industrial stack that you've defined and they can incrementally. take on projects that maintain and improve your operation without relying on a lot of system integration, without sacrificing governance and all the security which is critical. And when it's done on the cloud, can quite easily, as compared to before, scale it and deal with all the necessary things that good enterprise IT demands and for good reasons.

Alexander Krüger

So create a clear structure around governance, around the platform and then let the people do it. I think this is also something that a lot of customers of us feared, like saying, we now expose ourselves to new technologies or a new approach and we don't have anyone trained on it yet. But in our experiences, there are people who want to do something new, something different, and they will now emerge from the mass of the people and also create ownership. And if you combine that with an

Natan Linder

Yeah. Yeah.

Alexander Krüger

which is structure about what he is able to do, what he's not able to do and what is his like guard rails. This is quite a powerful approach to like save on cost like 10X.

Natan Linder

Yeah, least then the, fear is always a great excuse to do nothing or stay within the confines of whatever comfort zone, but it's definitely not the way to solve for your real needs to innovate basically. Cause operations is not just the end of your...

R and D process, whatever product you're making, it's, it's an integral part of it. You know, production lines are products that you can, you can build them and they can be an amazing power multiplier, or they can be just like, the weak link in, in, in, in the end of a chain of a huge R and D investment. And so it doesn't make any sense not to.

take this approach that is very aggressive on the technology and you see the the companies who changed stuff in the past decade or so and in here in the u.s. of course everybody talks about space x and tesla but there are many many others you know with the new e-companies or one of our great customers skydio and there's like other companies like that in around the globe but they've vertically integrated

a lot of their operation and especially when they're doing organic manufacturing as opposed to contract manufacturing. They're not just asset-lean and like they're kind of outsourcing their operational and their factory. We're going to take care of the whole process and this is what would make our product better. We can then, better support, we can distribute it differently and they're changing the game. And I think the numbers are going to speak for it.

Alexander Krüger

ownership.

Natan Linder

for itself and yeah.

Alexander Krüger

I think if you also look, we're from Germany and if you look at our automotive OEMs versus the Chinese ones, they pump out new models every six to nine months. Germany will not be able to set up a new line in their time. In their time, they fully iterates through the product.

Natan Linder

That is exactly right. Again, we've talked about this before, but this is why trying to get people to think in this new open ecosystem approach that allows you to integrate a lot of technologies and move faster. So that's one facet of it. But when you really think deeply, what do companies need to do? Because, OK, we're talking about the problems,

people are wondering, what's the general approach for thinking differently? And it's not just picking an architecture because that's an element of starting to work on this new solution, right? Or this new approach. I think it lies in the realm of designing, implementing new type of production systems. And a production system and this back to automotive, obviously stems from the origins of lean and where Toyota production system was invented, perfected, then, then was, I think propagated over, the past 40 years around the globe. the first principles of lean are still true, are still widely used, whether you do this formally or not, whether you have an operational excellence that believe in this variant of lean or that approach to Six Sigma or whatever it is. But the fundamentals are the same. You're waste, you know, reduce waste, and, move the value to the customer. You're continuously improving. So Kaizen, you're respecting the people doing the work and giving them the best tools and so on and so forth. And so while those.

first principles are the same. The tools to implement them are no longer the whiteboard and the clipboard or the spreadsheet or the highly integrated whatever five pieces of software you bought 10 years ago that whomever some system integrator put together, it has to be a different type of a production system. It needs to be more dynamic. It's fundamentally digital native.

You know, it needs to be open back to the ecosystem approach we were talking about. It needs to think about the people who are taking a part in that new production system as true knowledge workers. And in other words, and this is again, sometimes people don't like that I say that, but like there are every, if you say knowledge worker, you're basically saying who is not a knowledge worker. So in fact, we need to stop using this term knowledge worker because everyone is a knowledge worker. So therefore it's obsolete.

Alexander Krüger

Yep. Yep.

Natan Linder

And, cause otherwise you're saying, these people have the knowledge in my organization and they will, have knowledge and use data and whatever. And these other people will just, whatever will be like human robots of sorts. And in, in, in the world we live in today, definitely in the U.S., Europe, Japan, and many other countries, we don't have enough humans for operations. Certainly we don't have enough.

skilled units for operations. we cannot, organizations cannot afford to think about their workforce as non-knowledge workers. And so if you have all knowledge workers, therefore, you have to give them a new production system. You have to involve them and you have to make them as much as you can exist very naturally in a digital environment. that doesn't, you know, if you implement or adopt like some platform or some

whatever software package that is not enough because half the battle is not the which tech stack you exactly you've selected half the battle is the change management and getting an especially an enterprise large, you know, multinational corporations with hundreds of factories across the globe that need to that need to change. Otherwise they become obsolete. So I think I think this is

Natan Linder

The most critical thing is designing and implementing new digital production systems.

Alexander Krüger

When like double clicking on technology for the sake of it. So if we like, I take a step back when we started like the 2015-ish timeframe, also when like, where you already like a few years in the making, it was always like talking about the career.

Natan Linder

No, actually, we stepped out of MIT, September 2014. And we started operating. There was a lot of bootstrapping involved in the early days of Twitter, but we, I think we hired our first salesperson around, 2018 or early 2019. So we were like, working very, very close to customers and bootstrap mode.

Natan Linder

Yeah, I mean you can't build the type of product we wanted to build just based on our assumptions. had to do it. Tulip, always say this like Tulip was born on the shop floor. So it wasn't wasn't born in some office, you know, so.

Alexander Krüger

Yeah. I really also think this is a failure pattern of software companies in manufacturing. Having an idea validated roughly and then already starting scaling it, and then you get way less widget. I think there were a huge flood of predictive maintenance startups or IoT platforms, which were like in 2017, 18 timeframe manufacturing is still paper-based, agree. Everything is expensive and slow, agree, so let's start throwing money on it. But then you didn't figure it out yet and went in wrong direction and cannot steer anymore. So, yeah, fully agree with it.

Natan Linder

Yeah, I think the main thing that happened is that while operations manufacturing is different and you know, we talked about the complexity and all that, but it needs the same things, if you want to run at scale a network of data centers, so you need orchestration and you need, interoperability between the systems and you need logging and, all the tools that you can imagine to do that well.

How is it different? Why should tried, tested, true technologies, whether it's in the protocol side or the open source tooling that we have for whatever, for the data visualization or setting up different compute storage that the hyperscalers are giving. Why would that be any different for the massive data problem that operations represent?

In my world, the answer is it's a problem of tools. It's a problem like how do you, and sometimes we talk about Tulip, we try to give the same tools that we use to build Tulip. we're a bunch of software engineers and hardware engineers to the people who build production lines and labs and whatnot. And those people are engineers and they need engineering tools. You know, if I take away your GitHub, your

Alexander Krüger

Yeah, accessibility.

Natan Linder

I don't know, now I guess everyone is using some sort of AI model to code and some development pipeline of whatever sorts to allow you to continuously deliver software. You can't build a product. You just can't. And how do you close that gap? so again, to us, it's like thinking about them.

engineers as first-class citizens and giving them the best tools to do the work.

Alexander Krüger

I think it's really a lot about applicability. like data, like time series databases, streaming, message broker, connectivity is really solved since years, but it's still not in place because like people on the shop floor have like a really, really different skillset. They thinking letter logic, thinking lean, thinking like value stream, et cetera. They cannot like log into GitHub yet because it feels like awkward to them. So we need to wrap it.

Natan Linder

Right.

Alexander Krüger

To make it and they are also short like or close the skill gap that they have. I think this is something that manufacturing tools need to do on top of technology excellence.

Natan Linder

Yeah, and I can give a concrete example just building on that. For whatever, 20, 30 years, the concept of the classic historian, we're going to have a bunch of computers with raids, with replication sitting on premise, with a nice cold room that is locked up, the server room, and we'll have data flowing into that. And this is where we will have our data, like the historian data.

which is critical if you needed to analyze, you needed to adhere to regulation. If you're making a device that needs to go with electronic device history records, all that, it's great. yeah, I think time series databases and at scale networks with redundancy and failovers can give you like 99.999 % uptime.

can do the work better, faster, and actually give you better tools to do all these other things that classical historians did. like, when we collaborate with companies like, say, Snowflake, for example, then they're coming in with a modern ETL with all the things that comes along with that. you need a historian in the classical sense anymore? So for me the answer is clear, answer is no. Like, and actually if you're doing that you're staying behind.

Alexander Krüger

And it's also so expensive, but I think these, also like an interesting pattern, like all these IT companies, like if it's AWS, like the hyperscalers or specialized data tools, Snowflake or Databricks, like it's for them so, or MongoDB, it's so hard to get into manufacturing. They also don't understand like the, just give me the data via Kafka or MQTT. And like the way actually getting it there, like from the status quo of whatever you have in your production is such a hard step for them. So they need to partner, they need to partner with.

with us or like alternative tools to really get the data like in shape and in quantity that it really makes use of it. So it's a partner approach and this is also something that at all Tulip is really embracing I think over the last years really. So what would you say has changed from this? I would say again mid of 2010s everybody's doing full vertical from connectivity to application to now where everybody's more thinking an ecosystem approach.

Natan Linder

Yeah, I think we adopted very early on open ecosystem approach. And no, we just met in Hannover Messe just to put this in some quick example with numbers, right? At Hannover Messe, we released our edge drivers. I think we released about 700 from vendors

that are like across the board. This could be like, Zebra and Hexagon, Atlas Copco, all sorts of, because there's so many physical things you have to connect to your endpoints in operations to actually get the job done, whether it's a device measuring something, or if it's a machine spitting out information in OPC UA. And that is, again, reducing complexity of system integration and

It, it changes, the decision-making process that is, often I hear customers saying, well, we need to start, we can't start doing like, you know, smart workflows that use the AI and the analytics before we connect all the things. And how do you need to connect all the things? And then, that kind of starts a snowball of a lot of reasons why not to do things. And I think connectivity is commoditizing. I think, this is sort of the real value of an ecosystem. think that, the sort of walls of like, if you're like a developer that lived in, whatever Siemens, ecosystem, you just stay there, your career, entire career, or if you're in Rockwell, you're staying there your entire career. Like when you really go to the factory, when you look at what's out there,

You can see the PLCs, multi-vendor, the HMIs, multi-vendors, the data acquisition software, multi-vendor, the tools, various vendors. So you, you actually have to do that. Otherwise you will not support the customers because the customers will have to integrate so many things themselves. And that's what the power of an open ecosystem is bringing to the market. And I think it's critical to keep that up and we are very, very serious about that.

Alexander Krüger

One I hopefully inspiring question or like the elephant in the room for some. So AI is also like already in Hannover Messe. would say every, every company has now a new two stickers on YouTube marketing. CTAs was AI obviously and it was unified namespace. would say, how would you say, will it shape the landscape in five years from now and how does it already impact Tulip now and what will the Tulip impact like also in five years from now? What do you want to build there?

Natan Linder

Look, if you were there, we were there together in Hannover and every single booth had like some AI slogan. it's, and I recorded a whole podcast, with Maddie, our CMO on this after Hannover. it was between my summary is like AI was everywhere and nowhere. That's my summary because there's such a gap between the proclamations that we're hearing from a lot of companies that say, AI is ready and it's ready for scale and in operations, right? certainly, you can't pass your day without seeing like five new posts on LinkedIn saying, here's another agent. Here's another tool. Here's another way to do whatever in IT land, but in operation, the side effects of using AI forget, you know, the, even the ability, the access to actually use it in the context of a fresh environment, AI.

not used well can shut down a production line. AI not used well can make you lose a batch of active material in biopharma that is worth millions. So that risk is very much in direct tension with this AI is ready for scale and ready for impact. It will be, but if it's, and this is sort of our approach, but if it's not designed to be

fundamentally human centric that allows the people to safely kind of use it to do things that requires trust. when we think about AI, we put out our AI composer and you can drag a PDF and it would have a step to tell you what is the analysis saying and like, do you want to turn that SOP that is regulated and so on into an application. Then that's an example where you can create those trusts, much like developers trust, whatever cursor is telling them and, they iterate. So I think this will emerge and a lot of the stuff I've seen, I got to tell you, it's like, repackaging of old stuff.

sticking in different disparate AI experiences that go outside and it's honestly, I think, pretty risky because you got to start with sort of AI first as a modality because everyone is getting everyone in their lives. I'm speaking about how you would create the presentation for your daughter's birthday. So consumer level, people are starting to get very comfortable using this. And then they will go back to their work. And then they're back to not even Google. Sometimes they're still in paper. So operation actually missed the classical web mobile cloud revolution. Now it's on the path to miss the AI revolution.

because it's still catching up, know, a lot of solution are still, oh, we're doing cloud migration. It's like, great. You know, that was like 15 years ago. So we don't have time for, for, for, um, all of this. And, I think the urgency is there. this is where, we're focused on that. And so this is my answer. What, what happened in five years? Like, I think in five years, the world is more open, more composable.

Natan Linder

And AI first, especially for frontline operations. This is sort of where we see our responsibility to expand the ecosystem and bring people in. These are, you know, people are talking about, use this copilot in operation. No, we should be talking about like what kind of MCPs we're using in, in the world of operation. And that changes, by the way, the term you guys like to talk about, which is, UNS, which to me, it's like, yes, it's like an important topic, nothing new in that sense, because UNS is an abstract concept to me, know, a way of thinking, way of like bringing architectures that were very common for years and years and years in the classic internet, if you like, it's two operations. And it's not that it's becoming obsolete. It's becoming overridden by this approach of like, yeah, why do MCPs and, the protocols that would synchronize all our models are critical because they have the context of what job they're trying to do. So if you're trying to really build agents for operation and give people the stability to use them, you have to think like that. it's so, so in a way it's like a fundamental baseline and I think it will take less than five years, but that's the general direction, you know.

Alexander Krüger

Yeah, inspiring and interesting. I think this will be interesting years. So a lot of things are changing faster than the years before. Like if it's an AI or perhaps also the UNS, if it's a password, we will see. And what applications AI will enable, we will also see. But I think interesting years to come. It was a real pleasure to have you here. definitely.

Natan Linder

Yeah, absolutely.

Yeah, thanks for having me, Alex. It was great. We should do this again pretty soon.

Alexander Krüger

Wish all guests and heroes like a great time and stay tuned for the next episodes.

Natan Linder

All right, thanks.