Working with data to manage and improve business processes is key to staying competitive in today's economy. This is why it is essential to make data from large scale industrial environments easily available for state of the art software solutions. Yet, consistently querying, receiving, and storing sensor data reliably is much more difficult than it should be.

That’s why we are excited to announce the transition to our completely rewritten Sensorconnect microservice!

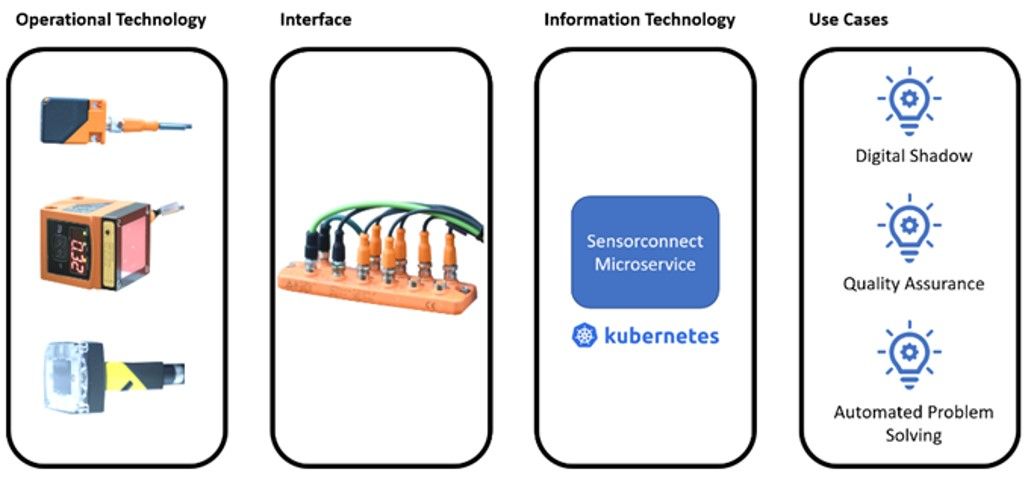

Sensorconnect is our Open-Source microservice for seamless sensor integration. It finds and reads out ifm IO-link masters in the network and pushes sensor data to MQTT / Kafka for further processing.

Why do we use data from sensors?

In industry, sensors are used to record real-time data about running processes and the condition of respective machines. As a result, process-relevant information and workflows become available, which in turn can be used for valuable insights in individual contexts.

There are three ways to collect those information:

- Connecting directly to the PLC:

This is possible for most modern machines that have a programmable logic controller (PLCs) installed that is able to gather relevant information about the machine. - Retrofitting Sensors:

Especially older machines are not equipped with any connectable hardware to read relevant information out of the machine itself. This is where a retrofit can help to gather required information by placing third party sensors (i.e. distance, vibration, inductive sensors etc.) on the machine. - Hybrid model:

The hybrid model is a combination of connecting directly to the PLC and the retrofit. In practical this means that relevant information is gathered through a connection to the PLC but also additional sensors are installed to gather even more insights. An example can be that the PLC provides the information that the machine is standing still while a button bar can provide additionally the reason for the stand still.

This is where Sensorconnect comes in place:

Sensorconnect helps to easily connect to all third-party sensors to correctly and properly capture the large amount of sensor data provided, ensuring proper interpretation for further use.

Our solution: Sensorconnect

We developed Sensorconnect to provide a plug-and-play readout of sensors. This enables effortless set-up of industrial IT infrastructure, reduces the time of implementation significantly and improves reliability and consistency immensely, especially in the case of brown field retrofitting with no OPC - UA availability.

The overall goal of our Sensorconnect solution is to make the large amount of production data available for various use cases.

Because we strongly believe in open industry standards, Sensorconnect brings the respective data to your preferred software solutions via MQTT or Kafka. This is also sometimes referred to as Unified Namespace. Moreover, Sensorconnect integrates seamlessly into the United Manufacturing Hub stack, providing scalable and reliable data management and storage as a result.

Technical features

Sensorconnect offers the following features:

- The automatic detection of ifm IO-link master in the network

- The automatic identification of IO-Link or other digital sensors connected to the gateways

- Constant polling of data from the detected sensors with a high frequency

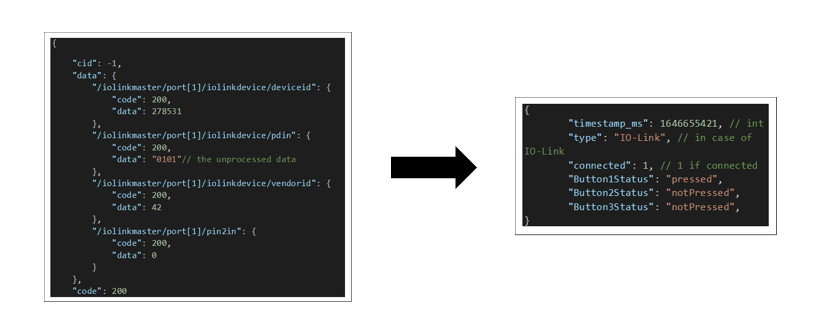

- Interpreting the received data based on a sensor database containing thousands of entries

- Sending the data in JSON format to MQTT and Kafka, for further data processing (e.g., using our standardized datamodel and Node-RED)

- The access to analog sensors with adapters like the DP2200

Try it out!

We are currently supporting the use of ifm gateways in combination with IO-Link sensors of all manufacturers. We plan on adding support for multiple different gateway manufacturers in the future.

Our focus lies on making production data available for a lot of different use-cases and not on controlling the production. Therefore, Sensorconnect currently does not support output to actuators on the shop floor. If there will be demand for this feature in the future, we intend to implement it.

Just access our open-source platform and try it out at the United Manufacturing Hub on GitHub.

You can also find the documentation to use Sensorconnect here.

Or just check out our Youtube video on setting up the United Manufacturing Hub, if you want to know how it feels like working with sensorconnect:

To learn more about our team, visit us at www.umh.app.