How can manufacturers unify data flows from hundreds of devices and still keep real-time telemetry, quality checks, and enterprise dashboards all in sync? In our latest episode of The Connected Factory podcast, we talk to Matthew Parris, Director of Advanced Manufacturing at GE Appliances, about his team’s journey from OPC UA to MQTT, the challenges of IT/OT integration, and a new industry standard called the CESMII API that promises to simplify how we read, write, and browse industrial data.

If you’ve spent any time wrestling with bridging factory devices, historians, and enterprise IT systems, you’ll appreciate Matthew’s hands-on experience. He leads the team responsible for “test equipment” inside GE Appliances: everything from verifying electrical safety to loading final firmware on the production line. In other words, data is his true product—and getting that data from point A to point B efficiently is a must.

We talk about three major points:

- Shifting from OPC UA to MQTT for Real-Time Telemetry

- Why QoS in MQTT Isn’t a Silver Bullet

- The CESMII API

Let’s break them down.

Key Takeaways

Shifting from OPC UA to MQTT for Real-Time Telemetry

- GE Appliances originally used OPC UA aggregators to gather data from various test stations. However, adding a new machine meant configuring multiple layers—first on the aggregator, then on the visualization system. This manual setup slowed down scale-up efforts.

- By switching to an event-driven MQTT architecture with Sparkplug, Matthew’s team eliminated extra steps. Once a new device comes online, it automatically “publishes” to the broker with a standardized format—no aggregator reconfiguration required.

- With more than 600 devices already connected, they drastically reduced system overhead while maintaining real-time insights on everything from voltage checks to final firmware updates.

Why QoS in MQTT Isn’t a Silver Bullet

- Many assume that using QoS 1 or 2 in MQTT guarantees end-to-end reliability. In practice, QoS only covers the connection between a client and its broker—it doesn’t ensure a message reaches all downstream or upstream brokers.

- In high-throughput environments, the two-byte packet identifier limit (65,535 in-flight messages) can also lead to silent data loss under heavy network disruptions.

- For telemetry data, GE Appliances found that QoS 0 with robust application logic was often more predictable: “fire-and-forget,” but accompanied by higher-level checks to ensure critical writes or reads weren’t missed.

Editors Note: The full article is now released about the QoS of MQTT

The CESMII API

- OPC UA, MQTT, and other protocols solve parts of the connectivity puzzle but can still leave you guessing “Which driver do I need next?”

- Enter the CESMII API, a growing industry effort to establish a universal, HTTP-based standard for reading, writing, browsing, and querying industrial data. Think of it as a “RESTful” approach to shop-floor data, where you can do everything—browse for available tags, query historical records, or subscribe to real-time changes—through a single set of endpoints.

- If widely adopted, the CESMII API could make industrial data retrieval as convenient as opening a web browser and typing a URL.

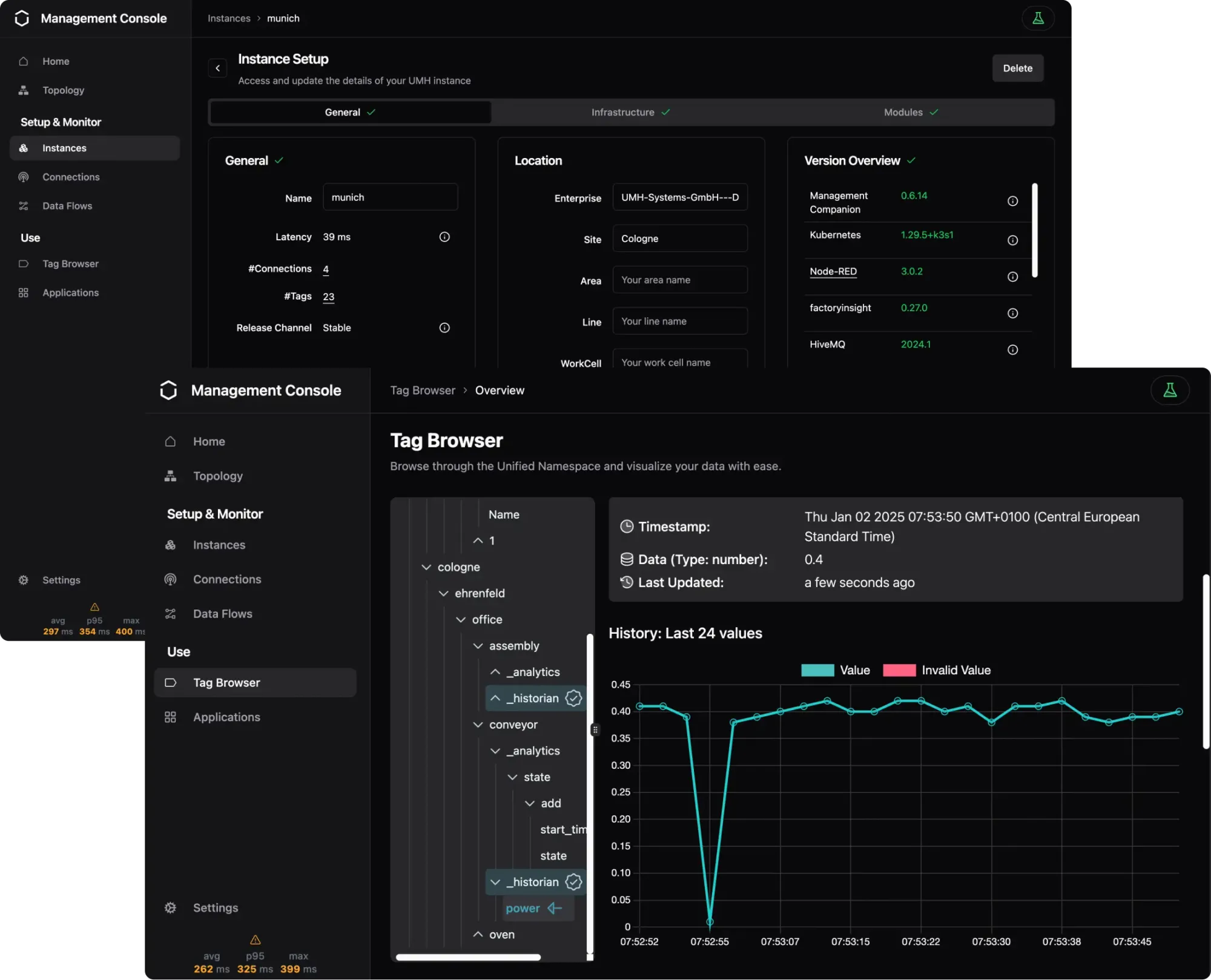

IT / OT Integration Platform for Industrial DataOps

Connect all your machines and systems with our Open-Source IT/OT Integration Platform to make all shop-floor data accessible at a single point.

Chapters

00:00:00 - Introduction

00:00:01 - Overview of GE Appliances & Matthew’s Role

00:03:07 - How Quality Checks Work in Manufacturing

00:07:02 - Bridging IT and OT in Factory Data Collection

00:11:29 - From Traditional IT to Unified Namespace

00:17:15 - Lessons Learned from Implementation

00:25:10 - Quality of Service (QoS) in MQTT

00:44:27 - The CESMII API Initiative

01:02:15 - Future of DataOps in Manufacturing

01:12:41 - Advice for IT/OT Integration Beginners

01:15:00 - Closing Remarks

Transcript

Jeremy: Right, so welcome to the Connected Factory. I'm Jeremy, co-founder and CTO of the United Manufacturing Hub. And with me is Matthew Paris. Hi, Matthew.

Matthew: Hello. Good morning. Good afternoon.

Jeremy: Good morning. Good afternoon. For me, it's currently 5:05 p.m. What is it for you? 11 a.m.?

Matthew: 11 a.m.

Jeremy: Oh, okay. Okay. Halfway doable. So welcome to today's podcast, where we will talk about DataOps, the CESMII API, and Matthew’s real-life experiences in the field of Unified Namespace and its integration. So, you work at GE Appliances. What is it that you do there?

Matthew: So, I’ve been at GE Appliances for about eight years. When I first started, I joined the test equipment group, and that’s where I still am today. In the test equipment group, we are chartered to drive the standardization of equipment going into factories to evaluate product quality. If you imagine that we are within a factory, the whole reason we are there is to make something.

There are various points along the way where we have to evaluate product quality. The checks we do include 100% in-line checks, offline audit checks (X% of production), and more extensive audits. The equipment used for those checks is the purpose of our team.

One of our big stakeholders is quality, but also operations since our equipment must integrate within production without creating bottlenecks. Many of our systems also integrate tightly with operators, so we have to consider ergonomics, footprints, and making sure they have the necessary information for their tasks.

I started as a test engineer, then moved into a director role, standardizing across all our factories. Recently, I also took on a second role—handling cybersecurity for our factories. We already have security measures on the IT side, but I focus on securing controls and equipment in the factory environment. We are starting some exciting projects in that space to create a safer environment from a cybersecurity perspective.

Jeremy: When we last talked, you mentioned that GE Appliances might not be a household name in Europe. You produce washing machines, microwaves, and other appliances, right?

Matthew: That’s right. We manufacture home appliances like washers, dryers, ovens, microwaves, dishwashers, water heaters, and refrigerators. We also have sister companies under Haier, like Candy in Italy and Fisher & Paykel in New Zealand. Competitors for us in Europe would be Bosch and Electrolux.

Jeremy: So, how does it work? These large appliances go through a production line, and your job is to ensure 100% of the equipment is checked? That includes electrical safety checks, flow checks, and more advanced quality measurements?

Matthew: Yes, exactly. We have three main categories of checks.

- Regulatory Checks: These are driven by agencies like UL (Underwriters Laboratory) and CSA (Canadian Safety Association). For example, we apply high voltage to the power lines and measure leakage to ensure people won’t get electrocuted when touching the metal chassis. We also measure ground bond resistance to ensure proper grounding.

- Quality Checks: These verify that the assembly process was completed correctly. We fold metal, paint, assemble motors, and more—all in-house. We test components electrically, making sure motors and other parts work correctly.

- Firmware & Value-Added Steps: We apply the latest firmware updates during production. Circuit boards arrive with an older firmware version, but we ensure that by the time they reach the customer, they have the latest updates. We also enable over-the-air updates for appliances already in the field.

Jeremy: This last point sounds like a critical moment where you got involved in IoT. But when I check LinkedIn, I see you also write about AI, networking, DHCP servers, and more. How did you get interested in these topics?

Matthew: Our team naturally spans multiple disciplines. One side is electrical engineering—designing equipment, measuring electricity, controlling processes, ensuring safety. The other side is IT-related—we provide data to the business. If our equipment didn’t produce data, we wouldn’t be doing our job well.

Our goal is to make sure every serial number that comes down the line is evaluated correctly in real-time. That means integrating everything up the stack—from the shop floor to enterprise systems—so operations and quality teams can make informed decisions. We handle everything from database technologies to MQTT, ensuring seamless data flow.

Jeremy: How did you first hear about Walker Reynolds and the Unified Namespace?

Matthew: It started in 2019 when I attended a Gartner conference in Orlando. I was looking for manufacturing trends and ways to improve our systems. I attended a session on blockchain, which was the big buzzword at the time. Someone asked, "I was sent here by my CIO to figure out how to secure our database with blockchain." That’s when I realized a lot of people didn’t fully understand what they were trying to implement.

The conference made me realize that while we were good at managing transactional data (quality records, production results), we had a gap in real-time telemetry. We lacked a way to see what our equipment was doing at any given time—voltage readings, relay states, sequence steps, timestamps. I started researching the best interface for this.

I explored Modbus, Sparkplug, OPC UA, and MQTT. Initially, we chose OPC UA. We used an SDK to integrate it into our software and connected it to an OPC UA aggregation broker, which Ignition then accessed. But OPC UA became unwieldy. We had issues with connection management, integration friction, and manually configuring new devices.

Eventually, our team suggested trying MQTT. It was a big shift—from a distributed point-to-point architecture to a single point of failure with the MQTT broker. But the integration experience was transformative. Once we connected a device, everything just worked. No more manual broker updates, no more manual subscriptions. We moved from managing 50-70 devices manually to over 600 devices with zero manual intervention.

Jeremy: What is CESMII API, and how does it fit into all this?

Matthew: CESMII API is an industry effort to standardize data access in manufacturing. Today, if you need data, you have to ask, “Do you have an API? A driver? A Modbus connection?” This is ridiculous in 2024.

CESMII API will provide a simple, standardized way to access industrial data, like how HTTP revolutionized web access. The goal is to create a single interface for reading, writing, querying, and browsing data—whether from an MQTT broker, OPC UA server, database, or historian.

Jeremy: Final thoughts—any advice for people starting in IT/OT integration?

Matthew:

- Don’t over-plan, but don’t start blindly. Think ahead, but take incremental steps and learn as you go.

- Solve real business problems. If you’re not delivering value, you won’t get buy-in.

- Build momentum through small wins. Start with a clear use case and expand gradually.

Jeremy: Thanks for the insights, Matthew! We’ll include all relevant links in the description. Stay tuned for the next episode!