Convergence

It’s maybe once in a generation that a new professional domain is born.

Labor, in the form of farmers cultivating crops, blacksmiths shaping metals into tools, and potters forming ceramic vessels, has existed since the dawn of civilization. The passage of time and toil eventually led to the century when Karl Benz kicked the tires on Patent-Motorwagen and John Deere turned his plow loose on the plains. By the 1800s, work that used to be performed by many small producers supplying tribes or villages became concentrated in factories, where labor and technology came together, and the seeds of the manufacturing operations domain were planted.

Accounting has similarly existed since humanity began trading goods thousands of years ago. Evidence of early forms of accounting has been discovered in early civilizations: Mesopotamia, Babylon, Egypt, Rome, and Medieval Europe had their own forms of bookkeeping, auditing, and even double-entry accounting. Fast-forward to the 20th century, and some of the earliest uses of computer systems in business were for accounting purposes. It was the convergence of the accounting domain and computer science that led to early business applications and the eventual birth of the information technology domain.

In 2024 we are on the cusp of yet another convergence, with manufacturing operations and information technology barreling towards each other.

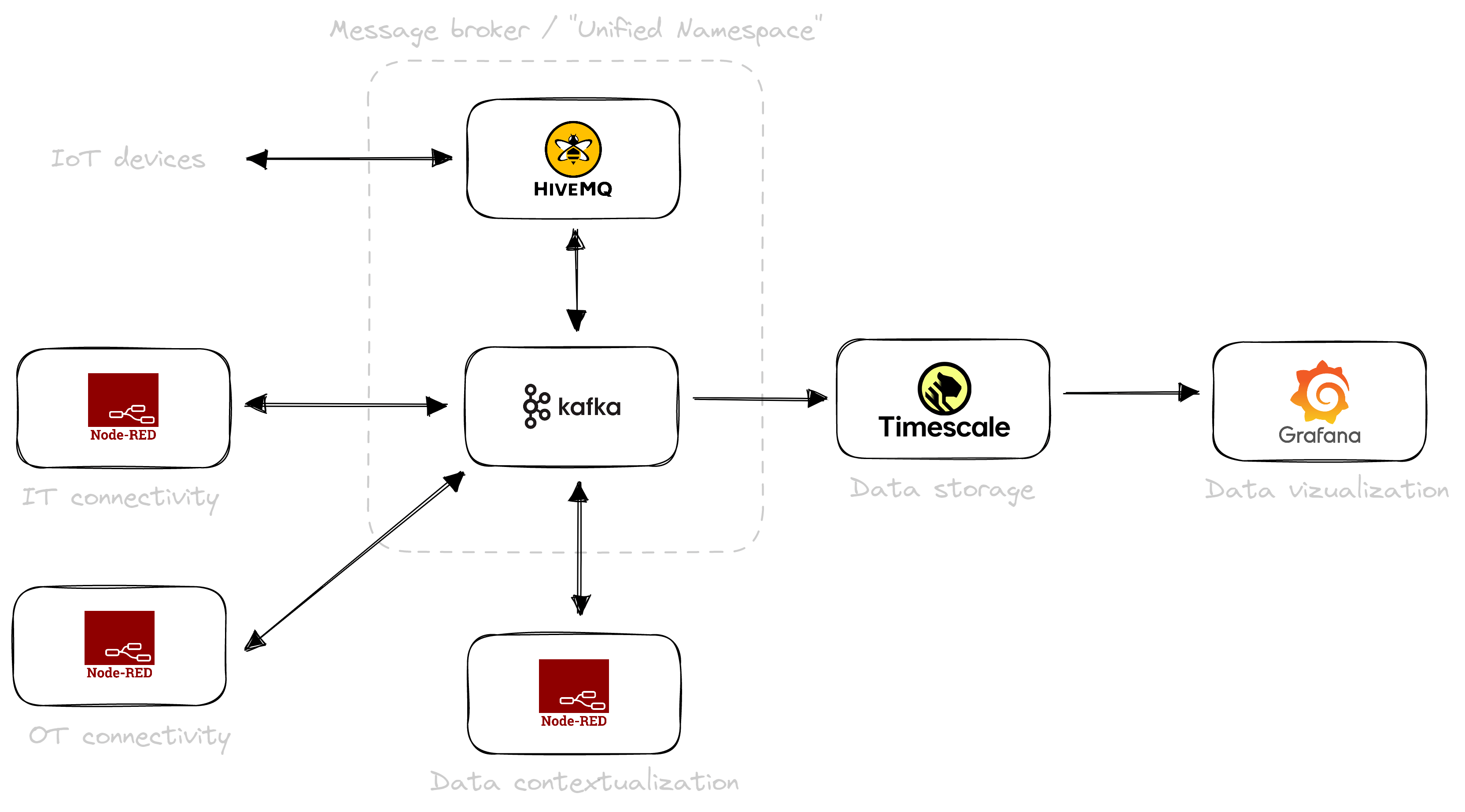

Each convergence is marked by the emergence of some emblematic object that serves to bring people together and improve how work is performed in the future. Manufacturing operations are epitomized by the buzzing automated factory performing a symphony of creation. Information technology, on the other hand, may be epitomized by the grand marvel that is the TPS report (sorry IT guys and gals, but we could all use some humbling from time-to-time). The emblem of IT and OT convergence is now starting to emerge. In the near future, we will find a hub for IT and Operations to gather around, watching data about all sorts of business activities flowing through it.

In this article, we’ll see how Systems Administrators (SysAdmins) fit into the Digital Transformation big picture. We will also explore reasons why I believe they will find the UMH business model fair and familiar, how the UMH helps close the gaps between Operations and IT, and why the UMH closely resembles the tech stack a SysAdmin would build themselves if they were starting from scratch.

How SysAdmins Fit into the Picture

Codename: Tech Tamer |

IT and OT convergence were once on a slow march towards each other. IT systems are a mainstay of the carpeted side of the business and have been for years. The valuable data generated by activity on the plant floor has historically been siloed from IT’s systems. When an IT system wanted to know about events that happened on the plant floor, a person keyed it, slowly and imperfectly, into the front office systems. This human factor has been, and remains, a mainstay for manufacturers’ operations. It is a factor that can hold manufacturers back because we are slow and imperfect creatures, but when we apply our creativity to solving problems, we set ourselves apart from the pack.

Let’s consider the roles that you'll find walking the spectrum from the plant floor to the data center. At the extremity on the plant side, you'll find machine operators, material handlers, and mechanics; these are the sorts of workers who may touch a computer twice a day — once at the beginning of their shift to clock in and a second time to clock out at the end of their day. On the opposite side of the spectrum, you'll find workers whose keyboards might as well be an artificial appendage as they count ones and zeroes to fall asleep at night. Software engineers sometimes reside so close to the beating heart of the IT beast it's difficult for them to envision life on the plant floor. Same goes for the person who reads printed pick lists to dutifully stage pallets at the dock — package dependencies mean something entirely different in their world.

So, if we walked from one extremity halfway to the other, who would we find in the middle? This would be the role who probably knows more people in the company than the HR manager, knows more about how IT systems are or aren't used than a developer, and they may or may not be an unqualified forklift operator (sometimes you need a little extra elevation on a Cat6 run, just don't tell that HR manager).

From account setups, to acting as an escalation point for the Helpdesk, to being boots on the ground IT anytime there is a major change at a facility, the Systems Administrator (SysAdmin) has experience than runs a mile wide. Because so much falls under their capable purview, they are drawn to solutions that enable them to accomplish the most as efficiently as possible and allow them to serve the broadest audience possible. So, what would be so attractive to them about the United Manufacturing Hub?

The UMH Business Model

As any SysAdmin will know, there are two types of vendors that exist. Those that cold call, provide opaque details about the product on their website, and stick a Sales inquiry form and a mostly-useless salesperson in front of anyone at the company who can actually answer real questions about the product. Then there are the vendors who “get it”.

These are the vendors who embrace the thriving (often times open source) community that champions their product, they eagerly provide it to new users to evaluate, and they maintain a tight feedback loop between their customers’ requests and their own product development teams. This is the behavior the UMH demonstrates.

For the sake of being objective, I must pause here for a moment. Open Source Software is not a silver bullet for democratizing access to powerful software and eliminating users’ costs. Ask any business that runs Linux. What the UMH offers as an open source product is generous, to say the least. The building blocks of the UMH are, for the most part, other freely available open source products. The blocks are glued together by UMH's open source glue, and packaged in their open source Kubernetes Helm chart (more on this in a later section). For anyone wishing to evaluate the UMH, it is an end-to-end usable product assuming the evaluator possesses the requisite amount of technical capability. Some of the UMH's proprietary features like the Management Console are lowering the technical bar. Still, expect to do more than click the “next” button half a dozen times to be whisked to the digital transformation promised land. Most evaluators are likely to end up wrestling a Linux terminal or poking around the helm chart at some point. On the plus side, by running the UMH in that Linux environment, you’ll never have to worry about Windows Server’s latest core-pair licensing shenanigan.

Commercially, the business approach taken by the UMH is a lot like Red Hat Enterprise Linux. Many features are freely available. These are the features that solve the problem of getting data from the plant floor into historian databases and displaying real-time on dashboards. Pretty much anything an evaluator would want to do to to prove the solution will “work” is available without paying a dime. Users who do pay receive additional features that solve business problems like meeting various compliance requirements, accessing platform management features for multiple users, and receiving support. Basically, you only pay once your use case has tipped from evaluation to production. Refreshing.

UMH Closes the Gaps in Understanding Between the Tech People and the Operation People

As mentioned earlier, a decent SysAdmin probably already has a better idea of what is happening on the plant floor than a software engineer whose entire job is debugging build pipelines and writing repetitive unit tests. That said, there is untapped potential for value creation when the gaps are closed between the manufacturing operations people, SysAdmins, and the most talented technical people like the software developers.

What are some of the reasons these parties don’t already work together closely? I would posit that many of the reasons are these things that were true “once upon a time”. IT departments hail from the carpeted side of the business. Their systems were less capitally intensive and they are motivated to provide the business shinier, upgraded, & modernized solutions. Attitudes like “move fast and break things” are born under these sorts of conditions. Failures are expected, and well-designed IT systems include redundancies to handle these failures gracefully. This is the antithesis of how things are in the OT world, where new production lines can be very capitally intense, downtime is unacceptable and the risk of changing is often far greater than the risk of not changing. An OT failure can result in extreme damages to the plant or to people. In today’s IT-dependent landscape, it seems tolerance level for IT systems downtime is much closer to OT systems downtime. It also seems like more adaptability is being asked of OT systems, in order to supply data to Machine Learning, Artificial Intelligence, and ultimately profit-enhancing IT solutions.

What are some of the factors that have begun to close these gaps? New technology, certainly. The theoretical capabilities of container management solutions like Kubernetes promise reduced risk of downtime in ways that appeal to both IT and OT. Lower cost hardware like SBC’s has leapt from the IT to the OT realm in some situations, and the increasing market penetration of things like MQTT on the OT side begets demand for IT platforms to run the brokers. Then there’s the people, who are better connected with communications tools like Zoom than they were in the past. The UMH takes advantages of these phenomena to further close the gaps. SysAdmins will have better signaling about what is happening in the OT world from the context provided in features like the UMH Management Console’s Network Devices page. And developers will be able to make use of the ManagementConsole API, enabling their applications to speak in their language to the UMH’s representation of the plant floor and get real-time information about device statuses.

The Norman Rockwell picture of OT and IT convergence has IT and OT gathered ‘round the table with a Grafana dashboard displaying UNS data projected on the wall.

As an OT Platform, it is what They Would Build Themselves, Built the Way They Would Build it Themselves

If you sat any SysAdmin down and asked them to connect the plant floor to an IT system with a tight budget for software licensing, after several iterations, they are likely to build something that very closely resembles the UMH. In fact, the origin story of the UMH pretty much went like that.

Incumbent vendors in the OT space had set themselves up to be disrupted by market forces driving down the costs of hardware and the software platforms that were capable of communicating with it. Manufacturers, especially those whose tight margins staved off major investments in the IT/OT convergence, have craved something like the UMH.

The building blocks have existed for years — Kubernetes, Kafka, and Grafana have been proven in countless deployments. A major challenge has been leveraging the open standards that allow these systems to be plumbed together, then maintaining the solution for the life of its deployment. The UMH delivers on these needs, minimizing administrative effort in performing maintenance on the system, and ensuring that upgrades are available automatically.

The UMH also comes with built-in compliance capabilities that would make the most tech-indebted, struggling-to-comply IT departments rejoice. The UMH is updated regularly, and has a Software Bill of Materials (SBOM). Legacy solutions and other open platforms that businesses are using to stay lean and efficient will readily interoperate with the UMH as long as they use some basic, open standards.

Land the UMH in Your Environment.

The United Manufacturing Hub (UMH) offers a compelling solution for bridging the gap between IT and OT in manufacturing environments. Its open-source nature, fair business model, and ability to close understanding gaps make it an attractive option for SysAdmins and companies looking to modernize their operations.

If you're facing challenges in integrating IT and OT teams, consider reaching out to a consultant for guidance. As a SysAdmin, you can propose the UMH as a maintainable alternative to legacy systems that are difficult to manage and update. A consultant can be particularly valuable in helping you build a compelling business case for the UMH. The UMH provides a robust, flexible platform that can adapt to your company's needs.

By implementing the UMH, you can streamline your operations, improve data flow from the plant floor to IT systems, and create a more efficient, collaborative environment. Take the first step towards IT/OT convergence and explore how the United Manufacturing Hub can transform your manufacturing processes.

Feel free to contact me for more information or assistance evaluating the UMH for your organization. I am based in Denver, Colorado and have been working with manufacturers in the Rocky Mountain region since 2019. Located somewhere else? No problem.