Every factory we walked into had the same problem.

A maintenance engineer can't figure out why machines keep failing. A manager can't answer "how much did we produce yesterday?" without three phone calls. A quality team can't trace a defect to its source. The data exists. Scattered across USB sticks, databases, Excel sheets on network drives. Maybe some data flows from a project a contractor set up years ago to make one connection work. No context. No metadata. Nothing reusable.

Data becomes what electricity already is: infrastructure every factory is built on. Today, a thousand cuts block the path.

USB stick installations. Physical presence to deploy. Two machines speaking the same protocol, unable to communicate. Four firewalls between data source and consumer. Every hour spent on unnecessary integration is an hour not spent creating business value.

Management calls this problem "time to value." How long from "we need this data" to "we're making decisions with it." It's a thousand small cuts. Each reasonable. Together they stretch weeks into months. This is why our mission is to build experiences that cut manufacturers' time to value.

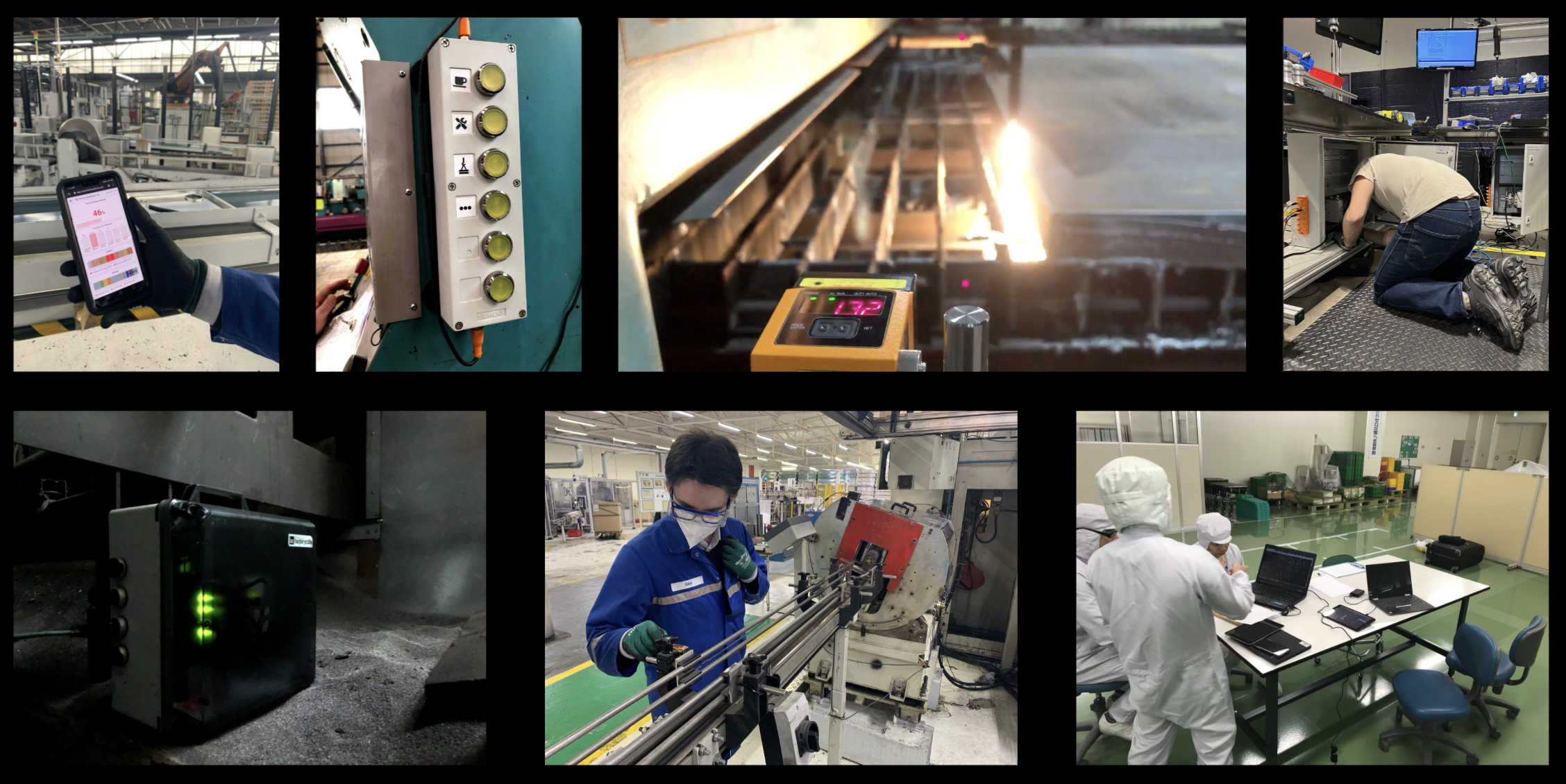

We've lived it. Before UMH, Alex and I ran a system integrator.[1] We traveled the world retrofitting machines. Tokyo. Singapore. Atlanta. Every factory had the same problem: data trapped behind a tangled mess of point-to-point integrations. Each connection built by a different contractor, carrying just enough data to work. Nothing more. We'd spend weeks understanding what existed before we could build anything new.

Our customers pay millions per year for legacy software they didn't choose. Legacy historians cost 100x more than modern databases at scale.[2] Ignition still uses Python 2.7. The vendors are stuck. Every update breaks someone's customization, so they don't release updates.

Most of this work is the same everywhere. The protocols are the same. The data structures are the same. The problems are the same.

Yes, every factory is special. Their manufacturing processes are unique, their competitive advantages are unique. Their data plumbing isn't. OPC UA and MQTT work the same way whether you're making car parts or beer.

Our customers' competitive advantage isn't in choosing between MQTT and OPC UA. It's in their scheduling, their processes, their domain expertise. We handle the plumbing so they can focus on what matters.

We built the thing we wished existed.

Why We Exist

We exist because data should be infrastructure. Today it's blocked.

The Unified Namespace is how we make it infrastructure. One place where all factory data flows. We focus on making it exceptional.

Getting there is where everyone fails.

“Let Microsoft/Amazon/whoever solve that problem for me” But they don’t come from the shop floor and don’t talk factory. Just look at the sheer amount of disbanded IoT products (Example 1, Example 2).

Buy from an existing automation vendor? They don’t want to make anything wrong and allow all customizations, and in the end they standardize without standardizing anything[3]. The only one who wins, are the SI’s who charge by the hour.

And hiring an SI? They charge for a project, then leave, and the knowledge leaves with them.

We built something that stays.

The juice subsidiary from Edeka has run UMH in production for three years. Böllhoff, HiPP, and others trust us across multiple factories.[4]

How We Work

How did we build something that stays? By working differently.

Own the outcome. Learn from mistakes. Focus on what moves the needle.

You own the outcome, not the task. When we saw our customers struggling with UMH Classic, we didn't blame the market or our customers. We owned it, redesigned the architecture, and released UMH Core.

We've let go of people who came from big companies where the goal was not doing anything wrong. You need to do things right, and for that you need to make mistakes.

Your best idea might be wrong. We lost a large enterprise deal after three years.[5] We were asking customers to understand Kubernetes and Kafka - complex infrastructure technologies that weren't making their work better, just more complicated. We adjusted. Now UMH Core is a single Docker container.

We first recommended MQTT to everyone.[6] Half right. We pivoted to Kafka. Half right again. The pattern that emerged: Kafka for the core, MQTT for the edge.

Today we use AI because it lets us iterate faster. We focus energy on reliability where it counts: the data layer. Everything else, we iterate on.

But fast iteration requires pushback. Real-time, from people who see what you're missing.

You can only discover patterns together. When tasks are well-defined, remote works. When you're figuring out what patterns should exist, you need the friction of real-time pushback. The 10-minute coffee conversation that prevents a three-day wrong direction.

We're office-first, but the office is for collaboration, not sitting alone at a desk. How often you come in depends on commute distance and what we're building together. Even remote team members join for onsite weeks every month or two.

Being office-first limits our talent pool. We're okay with that.

We hire for learning ability, not credentials. We need people who can learn fast, because we can't hand them patterns. They discover them with the team.

If it doesn't move the needle, don't do it. We tried process industries, energy, pharmaceuticals. Their pain was certification, not data costs. A 100x cheaper historian doesn't matter when your real problem is FDA compliance. They weren't feeling the pain we solve.

We've walked away from deals. Told customers: don't buy this, you're not ready.

So we killed building our own historian. If we do everything, we do nothing good. We've seen competitors try to be the entire stack. Over ten years and tens of millions later, still fighting for market share.

We killed MQTT as the primary transport.[6:1] It couldn't guarantee processing at the scale our customers needed.

What we say no to defines us more than what we say yes to.

Every hour has to connect to business value. Indirect work counts. Developer experience, unblocking colleagues, team happiness. But you need to know how it leads there.

What We Build

Infrastructure means one way to do things. Like electricity has standard voltage, data needs standard access patterns.

We design for the power user. The person in our customers' plants who gets shit done and has the respect of their peers. Not management. Not process engineers. The power user will champion and maintain it.

Getting started looks like drag-and-drop: device connections, data modeling, visual configuration. Going deeper means CLIs, AI agents, and whatever tools the organization already uses. The UI generates configuration that machines can read too.

One way to accomplish each task. One way to connect to an OPC UA server. One way to access the logs. One way. Not two for different teams. Not three to give someone flexibility. When every factory makes different choices, the next person who inherits the system can't understand it. One way means the same configuration works everywhere.

Auto-detect everything possible. Safe defaults mean doing nothing doesn't break things. If 95% of factories need the same setting, that's the only setting. Power users don't want more options. They want clean interfaces that let them get to the code when they need to.

Code is the escape hatch. Start with clicks, see the configuration it generates, take over in YAML when you're ready.

One person with AI can now build entire dashboards and configure hundreds of machines in minutes. The UI generates the same configuration that power users and AI agents read.

LLMs hallucinate. UMH doesn't.

Opinionated by design. Industrial software is designed to impress managers and procurement.[7] Infinite options, 18-month implementations. In the end, nobody wants to use it.

UMH has less flexibility than most expect. We designed it that way.

Our UX Standards spell out the details: 100ms feedback loops, no fake progress bars, progressive disclosure from clicks to code.

You can keep dying by a thousand cuts.

Or you can try something different.

Data becomes what electricity already is: infrastructure every factory is built on. We built the system to make that real.

If you want infrastructure that scales to 200 factories without 200 different configurations, try the community edition.

Alex, Niklas, and Jeremy

UMH founders previously worked as system integrators with top management consultancy on digitalization projects worldwide. See: Freigeist Backs United Manufacturing Hub ↩︎

See: The High Compression Deception: A Reality Check on Historians vs Open-Source Databases ↩︎

See Opinion: OPC UA is the Peak of All That Is Wrong in Manufacturing ↩︎

See: UMH Customers ↩︎

This experience led to UMH Core architecture. See: UMH Core vs Classic FAQ ↩︎

See: Tools & Techniques for Scalable Data Processing in Industrial IoT ↩︎ ↩︎