The central result is an overall process overview and a microservice architecture, with the help of which an industrial image processing system can be put into operation on the software side only by configuring the camera and entering the environment variables. Currently, cameras of the GenICam standard with GigE Vision interface and Cognex cameras are supported. The open architecture creates a basic platform for the development of further microservices and subsequent processes in the context of industrial image processing.

This publication was made by Patrick Kunz as a Bachelor Thesis for the “Institut für Textiltechnik der RWTH Aachen University” in cooperation with Kai Müller (ITA / RWTH Aachen ) and us.

Abstract

Objective of this thesis: The objective of the thesis is the development of a robust and user-friendly software for an industrial image processing system, which applies deep learning methods. The user of this software will be able to quickly and easily put an image processing system into operation due to its plug-and-play capability and standardized interfaces. The system software is based exclusively on royalty-free software products.

Solution process: For the development of the overall system, relevant standards, interfaces and software solutions are researched and presented. By dividing the system into sub-processes, functional requirements for the software are derived and implemented in the development with the general requirements in a system architecture. The implementation and subsequent validation is carried out in the model production for textile wristbands at the Digital Capability Center Aachen.

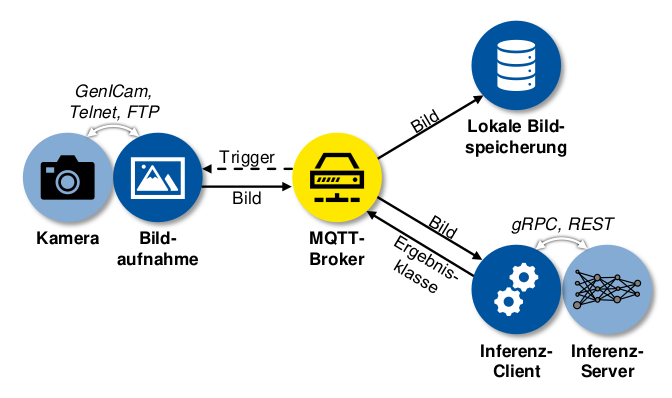

Key results: The central result is an overall process overview and a microservice architecture, with the help of which an industrial image processing system can be put into operation on the software side only by configuring the camera and entering the environment variables. Currently, cameras of the GenICam standard with GigE Vision interface and Cognex cameras are supported. The open architecture creates a basic platform for the development of further microservices and subsequent processes in the context of industrial image processing.

Key word: Machine vision, quality control, deep learning, microservice architecture, MQTT