Abstract

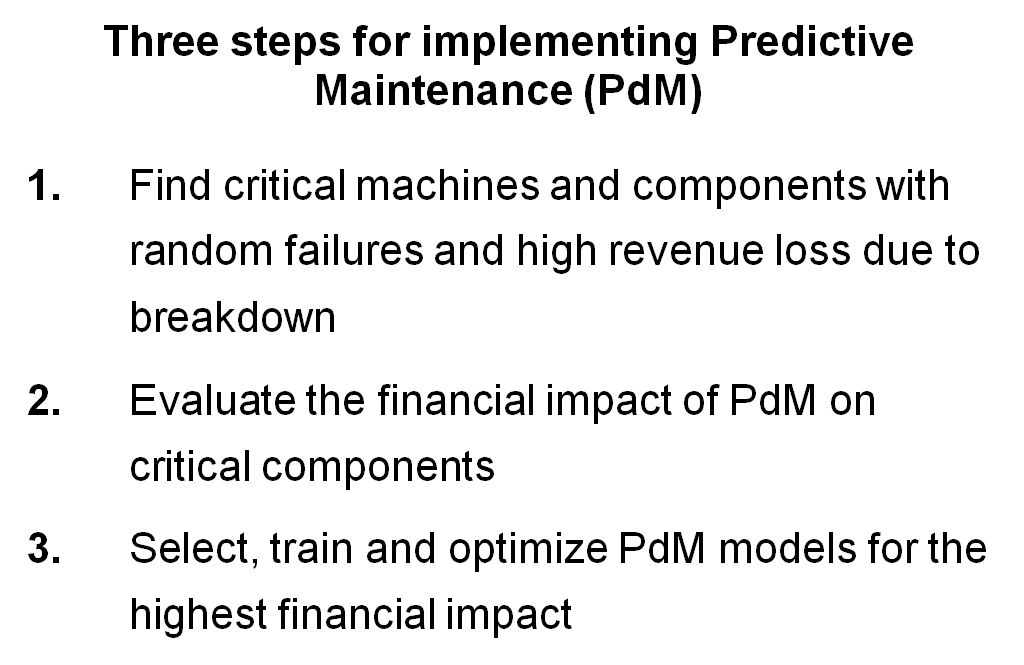

Objective of this thesis: The goal of this thesis is to develop a methodology to implement Predictive Maintenance (PdM) economically viable into a company. The methodology is then validated in the Digital Capability Center (DCC) Aachen.

Solution process: Maintenance strategies and machine learning algorithms are researched together with methods for optimizing productions lines. This knowledge is then summarized and validated in the DCC Aachen.

Key results: Because of high costs and effort PdM is only economically viable on machines and components with high revenue losses due to breakdown and where the failure is almost independent of uptime and wear. In the DCC Aachen the wind up bearing at the warping machine is identified as a component for a PdM implementation, but a combination of machine learning and existing sensors is not enough for an economically viable implementation.

Key word: Predictive Maintenance, maintenance strategies, machine learning