Control loops are very popular for regulation in OT as well as in nature. They are fairly simply at their core.

A set value is to be reached. For example your refrigerator is meant to reach a set value temperature of 4°C. Now a thermometer inside the refrigerator acts as a sensor to measure the current temperature. If the current temperature is too high, then the PLC will send a signal for the cooling elements to be powered, which act as the actuator in this process. Now the temperature will be gradually reduced until the temperature is around 4°C, at which point the PLC will notice the sufficiently low temperature and turn off the cooling elements until the temperature rises again. This loop will continuously go on and stabilize the temperature at the desired value. These type of value regulation can be done with many things, be in concentration, speed or as discussed here, temperature.

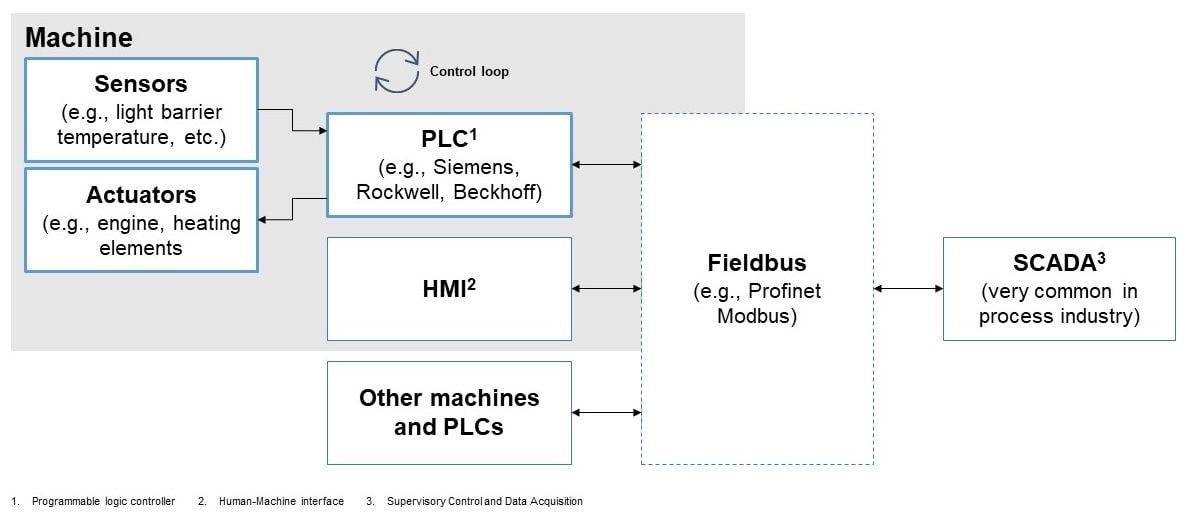

The image below shows a fairly generic example control loop. As you can see the sensors, actuators and the PLC are working together to regulate the specific parameters. Only the PLC them communicates outside the control loop.

Example of a control loop: PID

One particular example of a control loop is a PID. PID stands for Proportional, Integral and Derivative. It uses a control loop as described above, but uses proportional, integral and derivative measurements to regulate even more intricately.