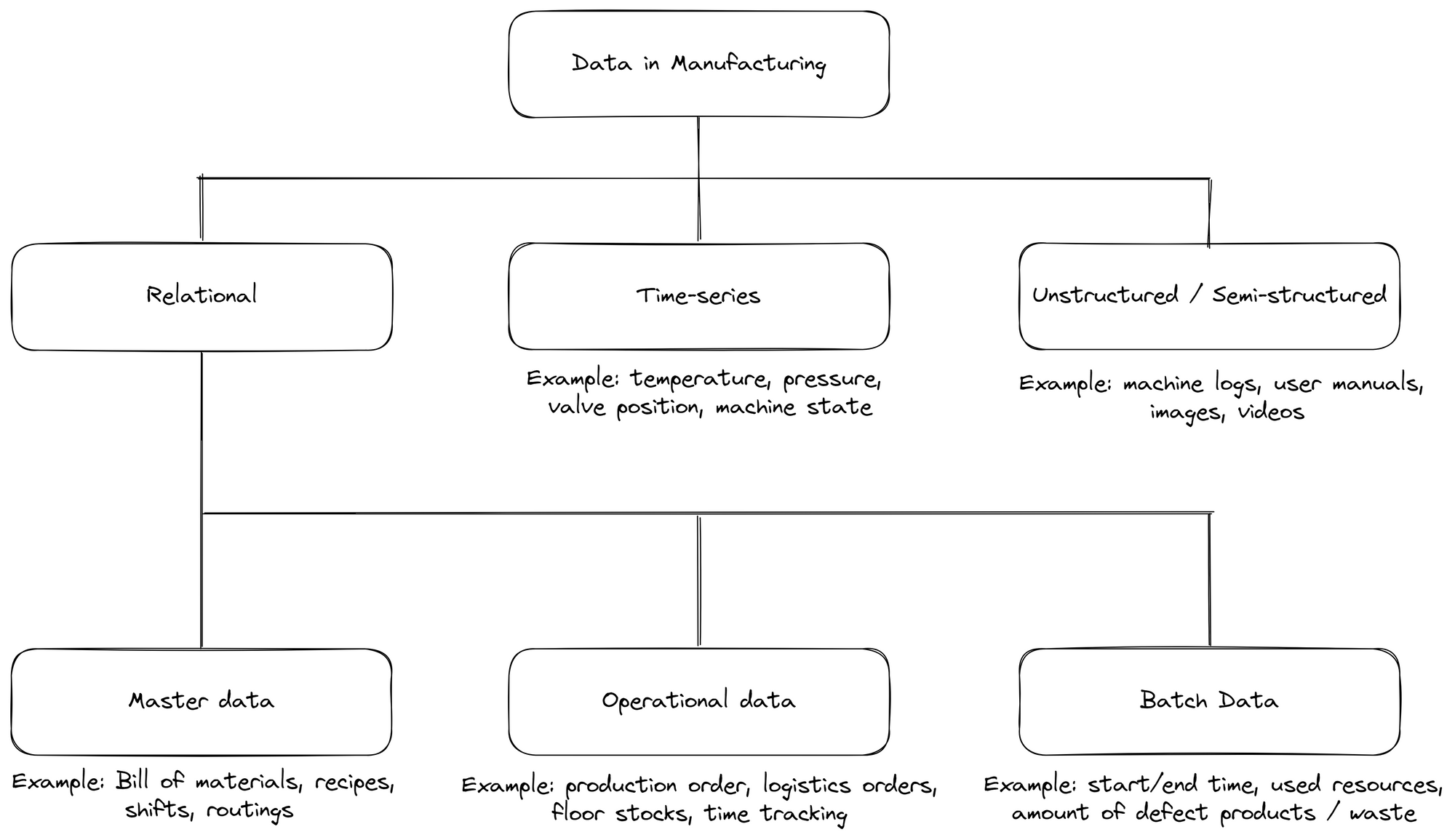

The lifeblood of modern manufacturing is data. It fuels insights, drives decisions, and enables smart factories to operate efficiently and innovatively. With the rise of Industry 4.0, understanding the types, structures, and storage of manufacturing data has become more critical than ever. In this chapter, we'll delve into the main archetypes of data commonly found in the manufacturing industry: relational data, time-series data, and semi-structured or unstructured data.

Relational Data

Relational data consists of information that forms a relationship with various data elements and is usually structured and stored in databases. This category is very often separated in into into further sub-categories: operational data, master data, and batch data.

Operational Data

Operational data encapsulates real-time actions within a manufacturing setup. It provides insights into production optimization, progress tracking, and swift decision-making. This includes handling production orders, tool assignments, logistics orders, floor stocks, and time tracking, among others. Data monitoring interfaces like the Production Operator Dashboard (POD) also contribute to operational data.

Master Data

Master data stands as the reference point for various manufacturing processes, providing information about products, suppliers, machines, and other core components. This includes Shop Floor Control units (SFCs), routings, Bills of Materials (BOMs), recipes, work instructions, resources, shifts, work centers, and more.

Batch Data

Batch data gathers information over specific time intervals or production runs. This type of data proves useful in industries like life sciences and chemicals that require a batch context for their time-series data. Examples: batch start/end, used resources, amount of defect products / waste.

Relational data is typically stored in SQL databases in a Unified Namespace (UNS) architecture. However, the data should never be written directly into this database in such an architecture.

Time-series Data

Time-series data, indexed by time, forms the backbone of operational data in manufacturing. Data points like temperature, pressure, or speed, recorded from different machines or equipment over time, offer critical insights for real-time monitoring, predictive maintenance, and analysis of overall equipment effectiveness (OEE). This type of data is usually stored in a time-series database, though a combined SQL/time-series database like TimescaleDB can also be utilized. It is also very easy to send them through a message broker.

Semi-Structured and Unstructured Data

This data category encompasses information that doesn't fit into a specific pre-defined data model. Unstructured data originates from various sources, including machine logs, maintenance records, user manuals, images, and audio or video files. Semi-structured data, on the other hand, lacks a formal data model but includes markers to separate semantic elements and enable record and field hierarchies within the data. This includes XML or JSON files from different operational technology devices or systems, typically used for configuration data or system communication.

Semi-structured and unstructured data is typically stored in blob storage such as Amazon S3 or in the device's file system. The lack of structure in these data types can lead to challenges in organization and analysis, but they also offer a wealth of information when handled appropriately.