To select suitable hardware components, a five-stage decision logic is developed and implemented as a software application, which suggests suitable components to the user depending on the specified use case and prioritizes them according to list price. In a simulative evaluation, this achieves complexity reductions between 73 and 98% and cost savings between 46 and 93%. A decision between Deep Learning and conventional algorithms can be made based on the given development circumstances as well as the complexity of image features.

This publication was made by Michael Müller as a Master Thesis for the “Institut für Textiltechnik der RWTH Aachen University” in cooperation with Kai Müller (ITA / RWTH Aachen ) and us.

Abstract

Objective of this thesis: The goal of the work is the development of a decision logic for the application case-specific selection of hardware and software for image processing systems for quality control in industrial production. On the hardware side the component’s camera, lens and illumination system are considered. On software side, it is decided, depending on the application, whether conventional algorithms or ventional algorithms or methods of Deep Learning are more suitable.

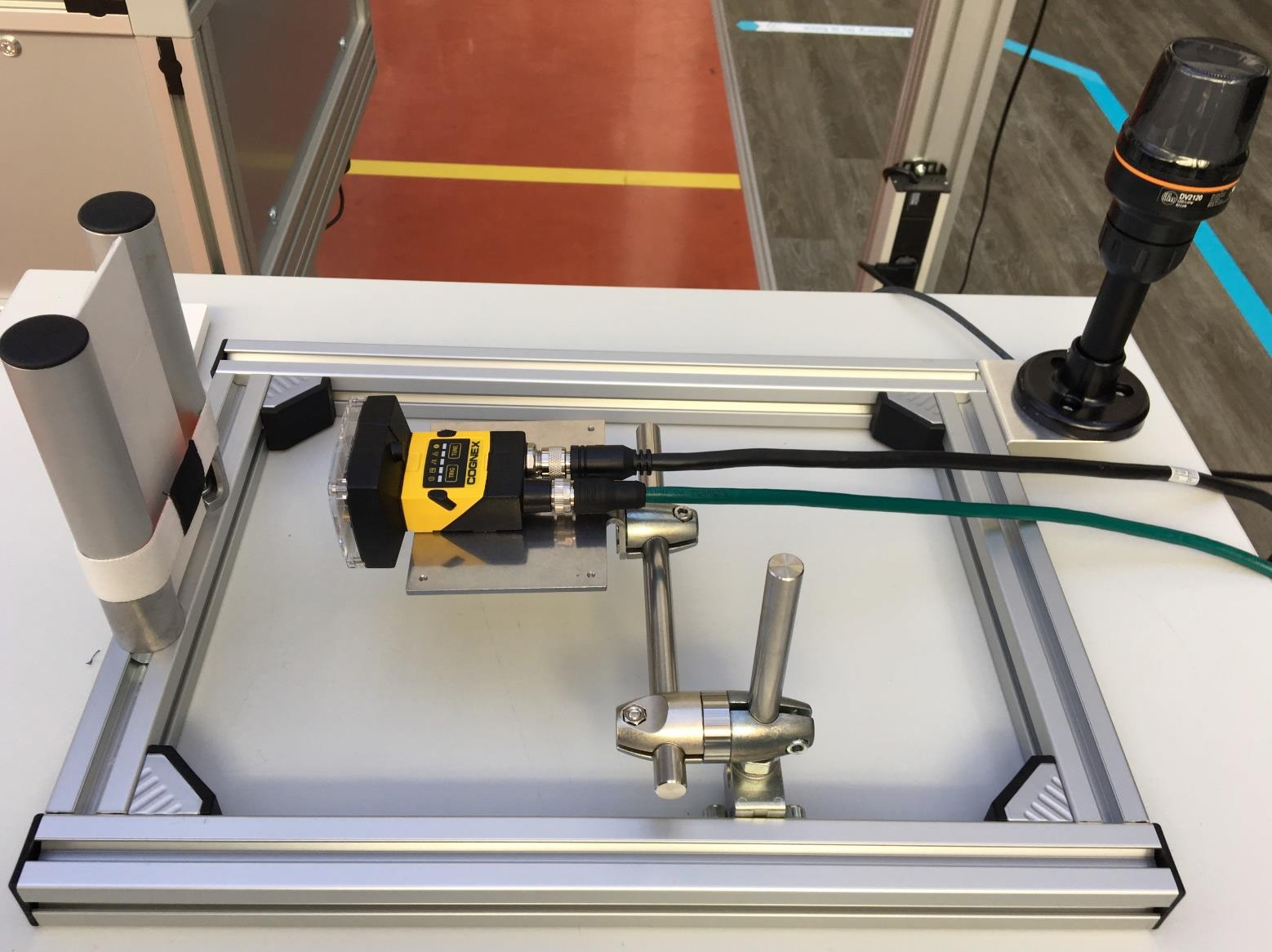

Solution process: Within the scope of a literature search, relevant descriptive variables for standardized for the standardized characterization of technologies and use cases. Furthermore, interdependencies between individual components and properties of the use case will be identified. By means of a market research, a database with concrete product information. Based on these steps, a set of rules for the selection of hardware and software technologies is derived and tested on a use case in the application case at the Digital Capability Center Aachen. The decision-making logic for selecting hardware components will finally be user-friendly computer application.

Key results: To select suitable hardware components, a five-stage decision logic is developed and implemented as a software application, which suggests suitable components to the user depending on the specified use case and prioritizes them according to list price. In a simulative evaluation, this achieves complexity reductions between 73 and 98% and cost savings between 46 and 93%. A decision between Deep Learning and conventional algorithms can be made based on the given development circumstances as well as the complexity of image features.

Key word: Digital quality control, Technical textiles, Mobiltech, Industry 4.0, Technology selection